Biotech products_Formulation

High-speed filling line for liquid injectable drugs

Contents

- Equipment that conforms to EU, U.S., and Japanese GMP

- Oversight of manufacturing of biological products by a manufacturing administrator

- Contract manufacturing of vial-packaged liquid injectable drugs using sterile manipulation

- Operations including raw material and material acceptance testing, weighing, formulation, sterile filtration, filling, and inspection processes

- Automated warehouse and shipping staging area with refrigerated storage to allow temperature control until product shipment

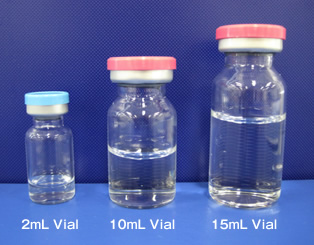

Vial sizes

Diameters of 16.0, 23.0, and 24.5 mm

We can accommodate vial volumes ranging from 2 to 15 mL.

Features

Formulation equipment

- By using traceable pipes to move biopharmaceuticals, which often must be kept refrigerated, from formulation equipment to filling equipment, we are able to control the temperature of drug solutions from 5°C to 15°C from the tank to the filling machine. In addition, we use two-stage sterile filtration, enabling us to formulate volumes of up to 900 L.

- We have a C/SIP-compliant spare dissolution tank (600 L) whose temperature can be regulated (from 5°C to 15°C).

- Capabilities include formulation of sterile drug solutions, handling of sterile active ingredients, and sterile sampling.

- Post-filter tanks and filling machine header tanks are equipped with agitators, allowing filling of suspensions.

- Alkaline-based washing is possible for some CIPs.

- We can accommodate formulation using fixed equipment as well as formulation using single-use bags.

Vial washing and dry sterilization system

- The cooled portion of our vial dry sterilization system has been fitted with a heat sterilization system.

Filler

- Our high-speed filling line can operate at up to 350 vials per minute (when using vials with a diameter of 16 mm).

- We use an in-process control (IPC) system to eliminate human error.

- We use a time pressure system to increase washing performance. In addition, we have installed a temperature correction system to increase filling precision.

- We can connect and fill drug solutions in low-volume, single-use bags (2 to 5 L), for example investigational new drugs.

Seamer

- Our seamer is installed under a laminar flow inside a sterile room.

Automatic testing equipment

- Inline automatic testing equipment enables us to carry out appearance and content testing on filling lines simultaneously.

Filling environment

- We have installed a closed RABS in our sterile room, enabling production in an advanced, sterile environment.