Pharmaceuticals (OEM) Manufacturing

Lyophilization Line~Vial Production~

Lyophilization Line Area 3

Lyophilizer and Automated Guided Vehicle (AGV)

We operate two Freeze-Dryers with a shelf area of 20 m2 and 27 m2.

An AGV allows vial loading/unloading in a sterile and dust-free environment.

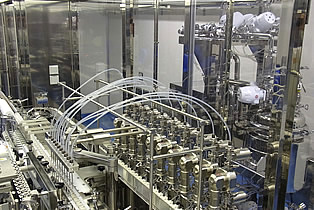

Filler

Using a temperature-compensated time pressure system, we strive for high accuracy in filling and integrity of CIP/SIP.

Liquid Blending Device

With a 300 L capacity for both preparation and filtration, this device can prepare between 40 L and 300 L of liquids under temperature-controlled conditions.

Lyophilization Line Area 6

Rubber plug washer

By adopting individual cleaning method, we pursue a certainty of removing foreign object.

Vial washer and tunnel type sterilizer

We offer sequence of process for vial's washing to sterilization, and drying.

Filling machine

A diaphragm pump ensures stable, high-accuracy filling. Filling volume is controlled with in-process control (IPC).

Lyophilizer and Automatic Guided Vehicle(AGV)

We operate two Freeze-Dryers with a shelf area of 27m2.

An AGV allows vials to be loaded and unloaded in a sterile and dust-free environment.